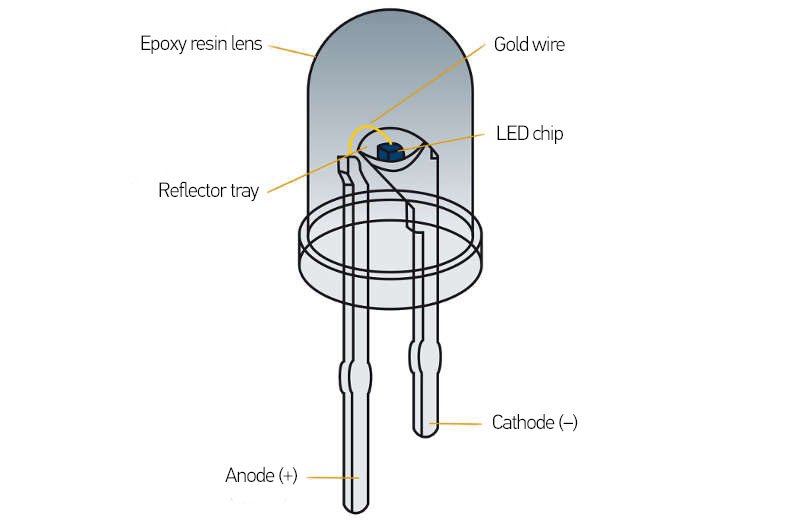

The LED chip is a solid-state semiconductor device. One end of the chip is attached to a bracket, one end is the negative electrode, and the other end is connected to the positive electrode of the power supply so that the whole chip is encapsulated by epoxy resin.

It is the core component of an LED lamp, that is, p-n junction. The led light-emitting chief function is to convert electric energy into light energy. The principal material of the chip is monocrystalline silicon. The semiconductor chip consists of two parts. One part is a p-type semiconductor. In holes dominate, the other end is an n-type semiconductor, mainly electrons. But when the two semiconductors are connected, a p-n junction is formed between them. When the current effect on the chip by the wire. Then the electrons complex with holes. Emit energy in the form of photons.

The wavelength of light is the color of light. Determine by the material forming the p-n junction.

Led Chips History

Fifty years ago. People knew the basic knowledge that semiconductor materials produce light.

In 1962, Nick Holonyak Jr. of General Electric Company developed the first visible light-emitting diode for practical application. LED is the abbreviation of a light-emitting diode in English. Its basic structure is an electroluminescent semiconductor material. It is placed on a lead frame and then sealed with epoxy resin. It is solid packaging. It can protect the internal core wire and have good seismic performance.

At first, led was used as the indicator light source of instruments and meters. Later, LED with various light colors was widely used in traffic lights and large-area display screens, resulting in good economic and social benefits. Take the 12-inch red traffic light as an example.

In the United States, people use a 140-watt incandescent lamp with long service life and low luminous efficiency as the light source. Will be produced 2000 lumens of white light. After passing through the red filter, the light loss is 90%, leaving only 200 lumens of red light. In the newly designed lamp, Lumileds adopts 18 red LED light sources. Equivalent to the light effect produced by a light bulb that consumes 14 watts.

Research Meaning

With the rapid development of LED technology and the gradual improvement of LED light efficiency, LED applications will be more and more widely. With the increasingly critical problem of a global energy shortage, people pay more and more attention to the development prospect of LED in the lighting market. LED will be a potential light source to replace incandescent lamps, tungsten filament lamps, and fluorescent lamps.

LED lighting market has broad development space. LED lighting applications developed indoor lighting from the outdoor landscape. According to the analysis, the development of LED indoor lighting will have an exponential growth trend in the next five years. In 2011, its output value reached tens of billions of dollars. In particular, in 2009, the EU took the lead in implementing the plan to ban incandescent lamps, and energy-saving issues have attracted much attention, creating an enormous market opportunity and optimistic prospect for LED indoor lighting.

The improvement of chip technology and lower prices are the keys to reducing the cost of LED lighting applications. With the rise of LED chip technology and LED luminous efficiency, the cost of a single LED chip continues to decline. At the same time, the large-scale production capacity release driven by upstream investment will trigger violent market competition, which will also put the decline of chip prices, which will effectively promote the low cost of LED lighting products. 2011, the supply of chips quickly changed from short supply to oversupply, and the price of chips fell rapidly.

For example, low power consumption 7.5mil×7.5mil blue light chip and high power consumption 45mil×2011, the price of 45mil blue light chip part dropped by 55.9% and 55.0%.

Whether it is high-power LED chips for hinge lighting and overall, or low-power LED chips for decorative lighting and some simple auxiliary lighting, the key to technology upgrading is how to develop more efficient and stable LED chips. In just a few years, with the help of a series of technological improvements, including the design of a new epitaxial mechanism of new chip structure and multi-quantum trap structure, the luminous efficiency of LED has achieved a significant breakthrough. These technological breakthroughs will pave the way for the popularization of LED semiconductor lighting.

Classification

MB Chips

MB chip definition is metal bonding chip; this chip is a patented

product of UEC

Features:

1. Using high

heat dissipation coefficient material – Si as substrate, easy heat dissipation.

Thermal

Conductivity

GaAs: 46 W/m-K

GaP: 77 W/m-K

Si: 125 ~ 150 W/m-K

Cupper:300~400 W/m-k

SiC: 490 W/m-K

2. The epitaxial layer and the substrate are bonded by a metal layer, reflecting photons at the same time to avoid the absorption of the substrate

3. The conductive

Si substrate replaces the GaAs substrate, which has a good thermal conductivity

(the difference of thermal conductivity is 3 ~ 4 times) and is more suitable

for the field of high driving current. 4. The bottom metal reflector is

conducive to the improvement of luminosity and heat dissipation

4. High power

applications can be increased the size, for example, 42mil MB

GB Chips

GB chip definition is glue bonding chip; this chip is a patented product of UEC.

Features:

1. transparent sapphire substrate replaces light-absorbing GaAs substrate, and its light output power is more than twice that of traditional (absorptive structure) chip. Sapphire substrate is similar to the gap substrate of the TS chip.

2. the chip emits light on all sides, with an excellent pattern diagram

3. in terms of brightness, its overall brightness has exceeded the level of the TS chip (8.6mil)

4. dual electrode structure, which is slightly inferior to the definition and characteristics of TS single electrode TS chip in terms of high current resistance

TS chip

TS chip definition is transparent structure chip, which is a patented product of HP.

Features:

1. The chipping process is complex, which is much higher than as LED

2. Excellent Reliability

3. Transparent gap substrate does not absorb light and has high brightness

4. Extensive used

AS Chip

Absorbable structure chip is AS Chip

Chip Type

- LPE:

- Liquid Phase Epitaxy

- VPE:

- Vapor Phase Epitaxy

- MOVPE:

- Metal-Organic Vapor Phase Epitaxy

- SH: GaAlAs/GaAs

- Single Heterostructure(

- DH: GaAlAs/GaAs

- Double Heterostructure

- DDH: GaAlAs/GaAlAs

- Double Heterostructure

The traditional LED chip adopts a formal structure, usually coated with epoxy resin and sapphire as the substrate. On the one hand, due to the poor thermal conductivity of sapphire, The active layer generates heat that cannot release in time, and the sapphire substrate will absorb the light in the alive area.

Even adding a metal reflective layer cannot completely solve the absorption problem; On the other hand, due to the poor thermal conductivity of epoxy resin, the heat can only be dissipated by the pins under the chip. Therefore, the front and rear two aspects cause the problem of heat dissipation, which affects the performance and reliability of the device.

Because of this, the flip-chip welding technology of LED came into being.

In 2001, Lumileds developed the power flip-chip structure, where the LED chips are a flip-chip link to a silicon substrate via bumps. In this way, the heat generated by the high-power LED does not have to pass through the chip’s sapphire substrate. But is transferred directly to the silicon or ceramic substrate with a high thermal, and then to the metal substrate.

The theoretical calculation of the thermal resistance of this structure can reach 1.34k/w at the lowest. However, the thermal resistance is directly proportional to the thickness of the heat sink.

The mechanical strength and thermal conductivity of silicon wafers are limited. It is difficult to further reduce the thermal resistance of the internal heat sink by thinning the silicon wafer.

Vertical Structure

Vertical structure LED chip has two basic construction: horizontal and vertical. The so-called transfer construction LED chip refers to the two electrodes of the chip being on the same side of the epitaxial chip.

Because the electrodes are on the same side, the current flows laterally in the N – and p-type limiting layers. It is not conducive to the diffusion of current and heat dissipation.

The vertical structure GaN-based LED chip with sapphire substrate developed by SemiLEDs has entered the market since November 2005.

Compared with the LED chip with a horizontal construction, the LED chip with vertical structure has the following obvious advantages:

On the one hand, the packaging thickness is thin. On the other hand, raise the yield and reliability.

Aging before

Larger diameter through holes. Or metal filler plugs and multiple through holes. Or Metal filler plugs raise the substrate heat.

Chip Size

High power

LED chips to have three sizes: 38 * 38mil, 40 * 40mil, and 45 * 45mil. The chip size can be customized, which is only a frequent specification.

Mil is a size unit, and a mil is one-thousandth of an inch.

The chip material and manufacturing process are also the main factors affecting chip power.

For example, Cree 40mil chip can bear 1W to 3W power, and chips of the same size as other brands can withstand 2W at most.

LED Chips Advantages:

The thermal conductivity of silicon carbide is 490w / m • K, which is more than ten times higher than that of the sapphire substrate.

LED Chips Disadvantages:

Silicon carbide is expensive to manufacture, and a corresponding cost reduction is required to achieve commercialization.

Led characteristics

1. The quad chip

2. Excellent reliability.

3. Widely used.

4. High security.

5. Long service life.

How to judge

Price of LED

chips: generally, the cost of lower chips is higher than that of round chips.

High power

LED chips must be higher than that low-power LED chips.

Quality of LED chip:

Bare crystal

brightness and attenuation measure led to chip quality.

Daily use

Red light:

9MIL regular square piece, (pure red) wavelength: 620-625nm, up and down 60 °, left and right 120 °, brightness up to 1000-1200mcd;

Greenlight:

12mil regular square piece, (pure green) wavelength: 520-525nm, up and down 60°, left and right 120 °, brightness up to 2000-3000mcd;

Performance:

It has the characteristics of high brightness, high anti-static electricity

ability, strong anti attenuation ability, and good consistency. It is the best

the choice for making LED signboards and LED luminous words.