What’s the LED light-emitting diode?

The light-emitting diode, like the semi-conductor laser, is a PN junction that emits light by injecting electrons into it from an external power source.

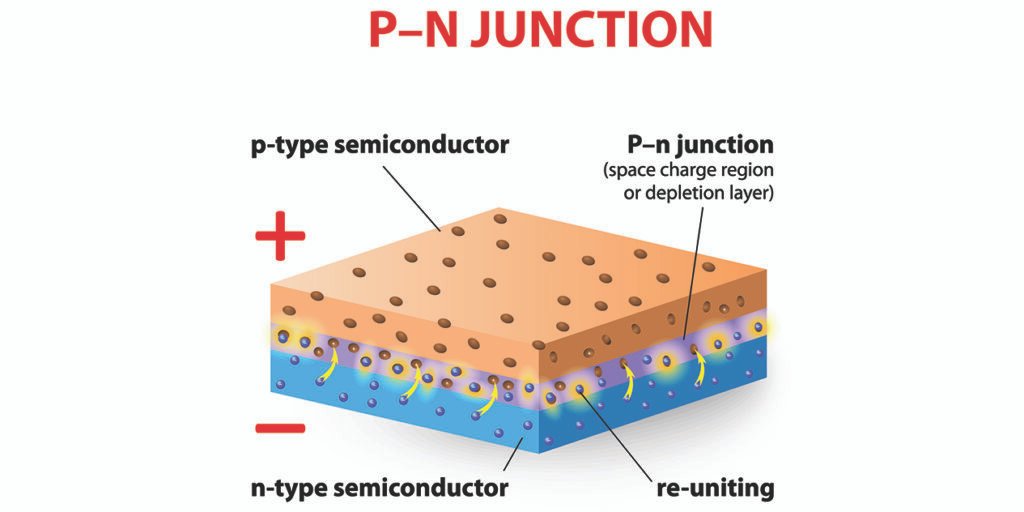

The core of the LED structure is the P-N junction, and the surrounding area is epoxy sealed with its lead and frame to protect the inner core wire.

When a forward current is applied to the P-N junction, the P-N junction can emit visible or invisible radiation, which is a composite light source composed of trivalent and pentavalent elements.

How does the LED light-emitting diode work?

A semiconductor diode is generally the use of PN junction unidirectional conductivity, PN junction with leads, and packaging to become a semiconductor diode.

A light-emitting diode is a special kind of diode. Like ordinary diodes, light-emitting diodes (LEDs) consist of semiconductor wafers, which are a List of semiconductor materials by pre-injection or doping processes to produce P and N structures.

Like other diodes, the current in the LED can easily flow from the P (anode) to the N (cathode), but not in the opposite direction. Two different carriers: holes and electrons flow from the electrode to the P-N structure at different electrode voltages.

When a hole and an electron meet and recombine, the electron falls to a lower energy level and releases energy in the form of photons, or light as we like to call it.

The wavelength (color) of the light emitted is determined by the forbidden band energy of the semiconductor materials which make up the P and N structures.

Because silicon and germanium are indirect bandgap materials, the recombination of electrons and holes in these materials is a nonradiative transition at room temperature, which does not release photons but converts energy into heat, therefore, silicon and germanium diodes do not emit light (they do at very low temperatures at specific temperatures and must be found at special angles, where the brightness is not obvious).

Light-emitting diodes are made of materials with a direct bandgap, so energy is released as photons, which correspond to near-infrared, visible, or near-ultraviolet light.

In the early days of its development, light-emitting diodes using gallium arsenide (GaAs) emitted only infrared or red light. As materials science advances, newly developed light-emitting diodes can emit light at higher and higher frequencies. Today, light-emitting diodes of various colors can be made.

The diodes are typically constructed on n-type substrates, where a layer of P-type semiconductors is deposited on the surface and connected by electrodes. P-type substrates are less common but are also used. Many commercial light-emitting diodes, especially Gan/InGaN, also use sapphire substrates.

Most materials used to make light-emitting diodes have very high refractive indices. This means that most light waves will be reflected to matter at the interface between matter and air. Therefore, lightwave extraction is an important topic for light-emitting diodes, and a lot of research and development has focused on this topic.

The composition of LED light-emitting diodes

The light-emitting diode, commonly known As “LEDs,” are made of compounds containing gallium (GA), arsenic (As), phosphorus (P), nitrogen (N), and more.

When electrons combine with holes, they emit visible light, converting electrical energy into light energy that can be used to make a light-emitting diode. Used as an indicator in circuits and instruments, or as a text or digital display. Gallium arsenide diodes glow red, gallium phosphide diodes glow green, silicon carbide diodes glow yellow, and gallium nitride diodes glow blue.

Because of the chemical property of organic light-emitting diode, OLED and inorganic light-emitting diode LED. Widely used for general lighting, automotive electronics, digital display, medical equipment, beauty nail, and so on.

The electrical conductivity of the LED light-emitting diode

Whether a crystal diode is a semiconductor or a conductor can be determined by its bidirectional conductivity. A light-emitting diode is bidirectional, it’s unidirectional.

For example, when we connect a light-emitting diode to a power supply, it will work on a forward bias and not on a reverse bias, whereas a conductor diode or resistance is bidirectional. So, led light-emitting diodes are semiconductors.

Unlike non-polar incandescent bulbs, LEDs can only emit light when a positive current flows through them. When a positive voltage is applied, a larger current flows through them, called a forward bias. If a reverse voltage is applied, the current will be quite fine (microampere-μa level), called reverse bias, and will not emit light.

So when the LED is connected to an AC voltage, only the forward voltage can make it light up, which will cause the LED to flicker at the frequency of the AC. Note that the reverse voltage the LED can withstand is lower than that of a normal diode, too high a reverse voltage will cause permanent damage to the LED.

Selection and use of LED light-emitting diode

Everyone’s conventional electronics knowledge led to lamp industry perception bias, which will limit our choice of electronic components, and light-emitting diode ability. If you want a mid-to-high-end LED light-emitting diode, but now the LED light-emitting diode industry is mixed, you must find a reliable light-emitting diode manufacturer.

Understand the light-emitting diode parameters, voltage, current, power, brightness, light-emitting angle, pad size, and the positive and negative electrodes of LED lamp beads.

Now, the LED light-emitting diode industry is becoming increasingly fragmented. That is to say, you want to find the led lamp bead specification model complete, which very likely is now by use, according to the specification model, by customer group classification is more.

If you’re looking for a light-emitting diode, the choice is rational. It’s not set in stone. It’s based on your light-emitting diode needs, age requirements, lights, general lighting, commercial lighting, medical Cosmetology, automotive electronics, industrial vision light sources, different needs, and the choice of models and supplier requirements also different.

At the same time, if you want to match the light-emitting diode manufacturer, be sure to match the actual light-emitting diode needs of your own company. And what is this actual demand, I suggest you directly and light-emitting diode manufacturers of customer service engineers directly consult or consult US experts, the effect will be more direct and efficient.

The pros and cons of LED light-emitting diode

Advantages

- high energy efficiency (efficiency of converting electricity to light), which means less electricity consumption.

• The reaction time is short and the scintillation frequency is very high.

• It has a long service life and is not affected by continuous flicker.

- 100,000 hours of life in a safe operating environment, with about 40,000 hours to go even at temperatures above 50 degrees Celsius. (8,000 hours for fluorescent lamp T8,20,000 hours for T5 and 1,000-2,000 hours for incandescent lamp) .

- Resistance to mechanical shocks such as vibration. As a solid-state component, it can withstand greater vibration than fluorescent lamps and incandescent lamps without any filament or glass shade.

• It is small and can be made very small (less than 2mm).

- It is easy to focus. Due to its small size, it is easy to achieve the required degree of concentration and dispersion using a lens, etc. . Occasionally, the packaging shape of the light-emitting lens can be changed. The light-emitting angle can be achieved by scattering the light from a large angle to focusing the light at a small angle.

Disadvantages

• It is monochromatic, with single-level photons of a single wavelength (as opposed to most artificial light sources) providing a wide range of pure colors without filters.

Disadvantages

• As the driving voltage of LEDs is low, the average household voltage is 100-240V. LEDs and transformers need to be packaged as light bulbs or tubes to be used at home. In consideration of cost reduction, many commercially available products are paired with poor-quality transformers, which speed up the possibility of damage.

• The light-emitting diode is not linear to the current and the photometric adjustment is slightly complicated, But the frequency must be high enough so as not to harm the eyes.

PWM dimming is a fast blinking method to adjust the brightness, such as 10% of the maximum brightness every 10 times, but a low blinking frequency will hurt the eyes, health risks are high below 1250Hz, and the risks above 3250Hz are as low as those of non-blinking dimming methods; and low-frequency PWM dimming for old fluorescent lamps will not hurt the eyes as the fluorescent lamps have an afterglow effect and LEDs do not.

• Higher costs and higher prices.

• Since light-emitting diodes are small and concentrated sources of light, they may be irritating to the eyes when used for lighting purposes, optical design is required to disperse the light sources.

• For each light-emitting diode will vary in its characteristics (brightness, color, bias, etc.) due to technical problems in production, even for the same batch of the light-emitting diode.

In short, a light-emitting diode is a semiconductor source that emits light when an electric current passes through it — an electroluminescent semiconductor electronic component in which electrons combine with electron holes to release energy in the form of photons.

Finally, does this knowledge help you? If it‘s helpful for you or you want to know more about LED lights, please feel free to leave us a message in the discussion area or contact us in the following ways. Best wishes to you!

Website: www.enetcl.com

Whatsapp: +86 158 7620 7215

E- mail: anna@enetcl.com