The basic structure of LED is a semiconductor P-N junction. Experiments show that the temperature of the P-N junction will rise when the current flows through the LED device. Strictly speaking, the temperature of the P-N junction region is the junction temperature. In general, due to the small size of the device chips, we can also consider the temperature of LED chips as alignment.

Usually, because the device chips have a tiny size, we can also regard the temperature of the LED chip as an alliance. The junction temperature is the active region of the LED, that is, connecting the diode to the base point, and where electrons jump between the two semiconductors to produce photons. Lower junction temperature helps LEDs to generate more light and reduces light decay. The junction temperature is affected by driver current, thermal path, and ambient temperature. When working in LED, four conditions cause the junction temperature to rise to various degrees:

- There are exact resistance values in the poor electrode structure of the device, the material of the window layer substrate or junction region, and the conductive silver glue, which are added to each other to form the series resistance of the LED. When the current flows through the P-N junction, it will also flow through these resistors, resulting in joule heat, increasing the chip temperature or junction temperature.

- Because the P-N junction cannot be highly perfect, the injection efficiency of the device will not reach 100%.In other words, in addition to the charge (hole) injected into the N region in the P region during LED operation, the N region will also inject charge (electron) into the P region. In general, the latter kind of charge injection will not produce a photoelectric effect but will consume by heating. Even if the researchers injected the charge into the good part, it will not all become light. Some of it will eventually become hot when combined with impurities or defects in the junction region.

- Reputedly practice that the limitation of luminous efficiency is the main reason for the increase in LED junction temperature. At present, advanced material growth and device manufacturing technology can convert most of the input electrical energy of LED into optical radiation energy. However, because the material of the LED chip has a much larger refractive index than the surrounding medium, most of the photons (> 90%) generated in the chip can not successfully overflow the interface but produce a total reflection on the interface between the chip and the medium. It returns to the inside of the chip and absorbs it through multiple internal reflections to the final chip material or substrate. It becomes hot in the form of lattice vibration, which increases the junction temperature.

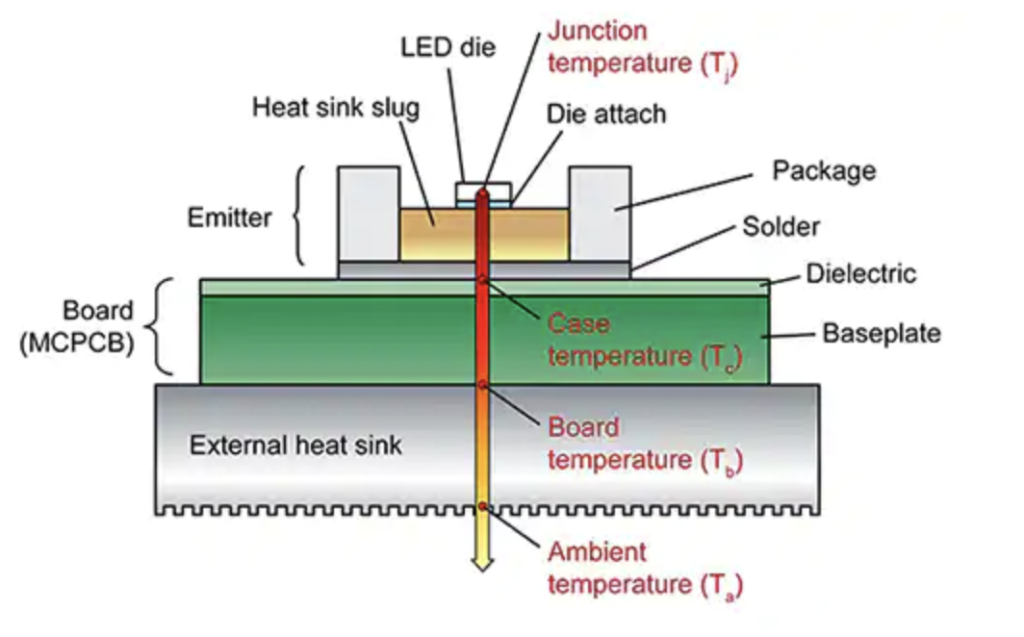

The heat dissipation ability of LED devices is another primary condition to determine the junction temperature. When the heat dissipation capacity is strong, the junction temperature decreases.

- On the contrary, when the heat dissipation capacity is poor. And the junction temperature will increase. Because the epoxy adhesive is a low thermal conductivity material, the heat generated by the P-N junction is stiff to radiate upward into the environment through the transparent epoxy. Most of the heat passes through the substrate, silver paste, tube shell, epoxy adhesive layer, and PCB, and the heat sink diverge downward. The thermal conductivity of related materials will directly affect the thermal dissipation efficiency of the device. For a common type of LED, the total thermal resistance from the P-N junction to the ambient temperature is between 300C / w and 600C / w. For a power LED device with a good structure, the total thermal resistance is about 15-30 ℃ / w. The enormous difference in thermal resistance shows that ordinary devices can operate normally only under circumstances of tiny input power when the dissipated power of power devices can be as high as watt level or even higher.

The basic structure of LED is the P-N junction of semiconductors.

The experimental results show that when the current flows through the LED element, the temperature of the P-N junction will increase. Strictly speaking, The researchers defined the temperature of the P-N junction as the junction temperature of the LED. Usually, because the chip size of the device is tiny, we can regard the temperature of the LED chip as the junction temperature.

The harm of LED junction temperature:

- The increase in temperature will shorten the life of LED. The lifetime of the characteristics of LED is its light decay. The longer the time, the lower the brightness until people finally extinguished it. We generally define the decay lifetime of LED luminous flux as 30%.

(2) High temperatures will cause permanent damage to the LED. LED encapsulates more silicone. If the junction temperature exceeds the solid-phase transition temperature (typically 125 ° C). The packaging material converts to rubber, and the thermal expansion coefficient suddenly increases, causing the LED to fail to open.

(3) The increase in temperature will decrease the luminous efficiency of LED. With the temperature rise, the radiation recombination probability of electrons and holes in the potential trap decreases, resulting in non-radiative recombination (heat generation), thus reducing the internal quantum efficiency of LED.

If you want to know more about lighting-related consultation, please feel free to consult: www. enetcl.com. At the same time, we hope you can give us valuable advice or suggestions. Thank you!